Metal production

- Overview

Damage control, before it happens...?

At WHsensors, our focus is to protect lives and livelihoods by producing specialized products to counter the hazards that you face every day. With years of experience in critical applications, our reputation for safe, rugged and reliable pressure instruments has been earned one customer at a time.

Our experience with hazardous environments and destructive processes has led to purpose-built pressure instruments for installations where interaction with explosive gases or corrosive media is routine. Even the pressure of slurries that will likely clog a gauge or switch can be easily measured through an isolation ring, ensuring an uninterrupted process flow along with continuously accurate measurements.

With the help of our able technical support, you can confidently monitor your processes with instruments that will keep your people safe and your operation productive. Just tell us about your application.

Depending on the production process and the type of metal, different additives are required in the manufacturing process. The products are stored in silos or concrete bunkers and are normally fed in via conveyor belts. Strong dust generation during filling and the often abrasive media severely limit the repertory of measuring principles suitable for this level measurement.

Configuration example:

WH131 Series

WH131 Series

0-100 PSIS

4-20mA output signal

316L SS with internal restrictor

CE

WH311 Series

WH311 Series

0-100 PSIS

4-20mA output signal

316L SS with internal restrictor

CE

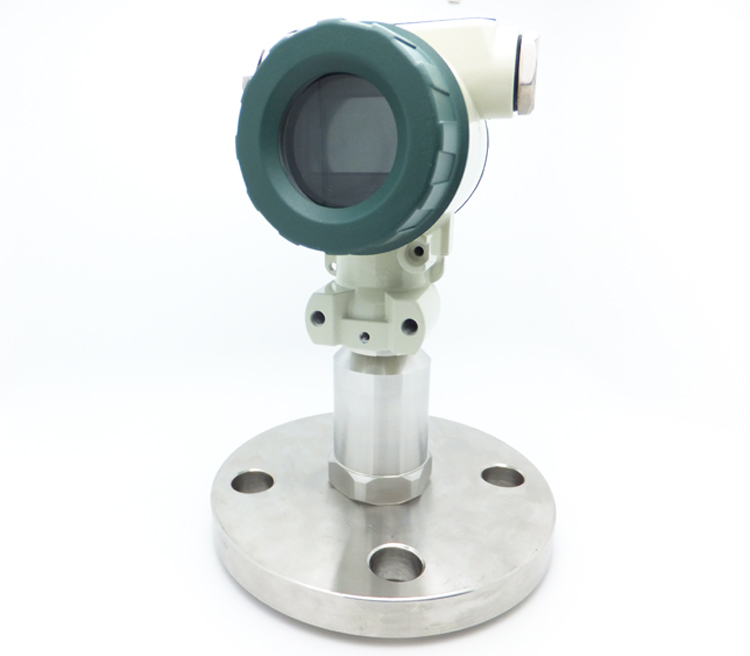

WH2088FLSeries

0-100 PSIS

4-20mA output signal

316L SS with internal restrictor

CE

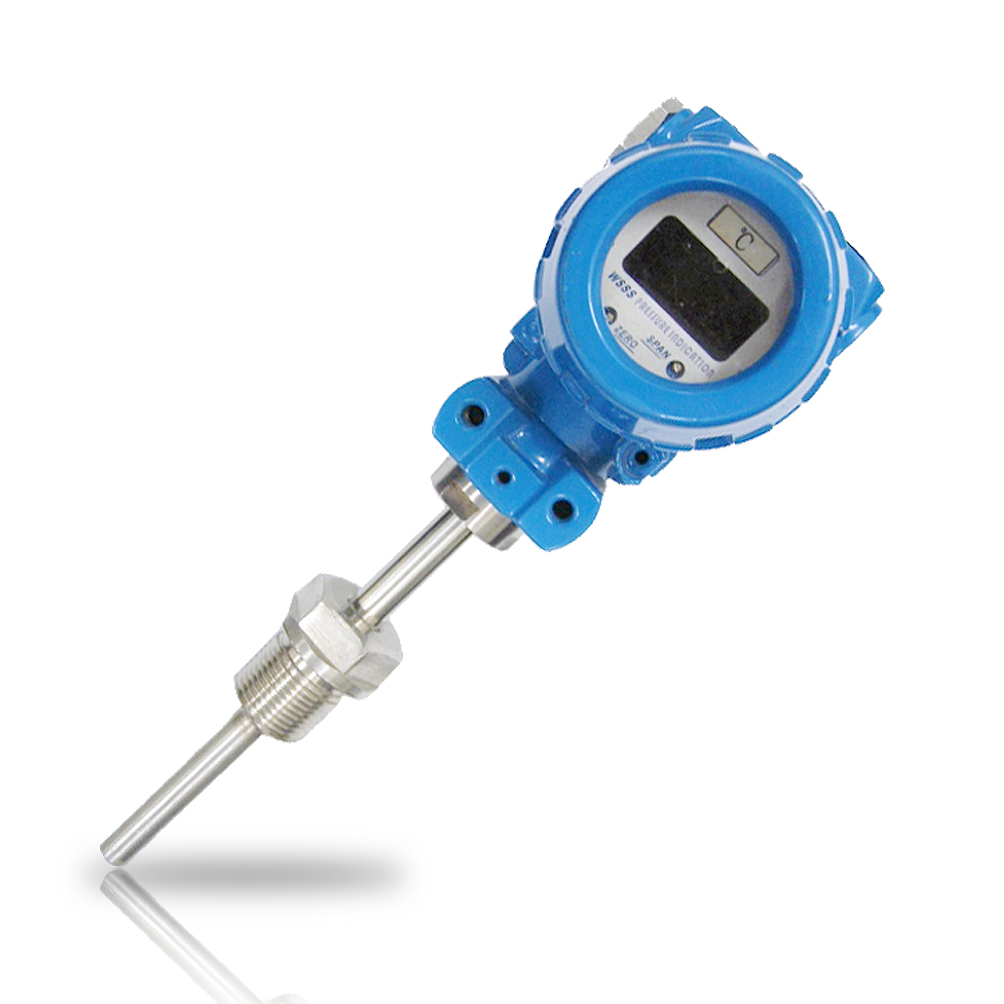

WH300Series

0-1600℃

4-20mA output signal

316L SS with internal restrictor

CE