HVAC

- Overview

In an energy-conscious world, you're constantly challenged to improve indoor air quality and operating efficiency while adhering to stringent regulations. As measurement experts, we develop products that maintain tight controls, allowing you to reach peak efficiency, reduce costs and keeping your customers in good health and comfort.

With an increased pricing on utilities, many homes and businesses are focusing efforts to reduce energy costs. Using pressure sensors to assist with monitoring pressure can aid in the selection of the type of power used (steam vs. electric) as well as monitor the efficiency of a device before it requires maintenance or replacement. Government funding has also increased in order to help municipalities and businesses "go green" through energy reduction programs.

WHsensors Features

-

One piece stainless steel construction

- no internal seals or gaskets. - High cyclical life (>100 million full cycles)

- Pressure ports include: 1/8" NPT, 1/4" NPT, SAE4 male and female

- Excellent long-term stability

-

Compound ranges with linear output through zero

(i.e.: -14.7 to 100PSI, -14.7 to 500PSI) - High level of EMI/RFI protection

Applications

- Refrigeration Pump Controls

- Chillers

- Freon and Ammonia Cooling Systems

- CO2 Systems

- Building Controls

- Water Pressure Systems

- Boiler Controls

- Environmental Test Chambers

Ammonia Pressure Applications

Pressure sensors for ammonia and other HVAC/R applications require special attention to media compatibility and environmental conditions. Ammonia offers refrigeration pump and compressor manufacturers an improved efficiency over Freon based systems. However, the thermodynamic behavior of ammonia is very different from Freon. When the refrigeration pump turns on, the ammonia temperature rapidly changes from 100°F to -70°F or below. This accelerated change, along with the type of sensor diaphragm material affects the pressure transducer performance and ultimately the control system.

O-ring sealed pressure sensors cannot withstand rapid thermal changes and over time the internal O-ring will fail. Fluid filled pressure sensors suffer from freezing effects. This causes a rupture of the thin diaphragm membrane, which is welded in place to hold in the silicone oil-fill.

Thin film technology sensors [based on 15-5 and 17-4PH stainless steels] that have their diaphragm welded to a pressure port, will undergo thermal stresses that will eventually crack the steel.

First,WHsensors utilizes its one-piece stainless steel sensing element with 316LSS wetted materials.

This element is free of welds, oil-fill and internal O-rings. Next, a special non-clogging port design is used in order to minimize the effects of extreme temperature change. The pressure sensor will recognize a uniform temperature as to maintain system stability. To conclude, This option can be added to a variety of pressure ports including 1/4" NPT male and 1/8" NPT male.

This element is free of welds, oil-fill and internal O-rings. Next, a special non-clogging port design is used in order to minimize the effects of extreme temperature change. The pressure sensor will recognize a uniform temperature as to maintain system stability. To conclude, This option can be added to a variety of pressure ports including 1/4" NPT male and 1/8" NPT male.

Compound Pressure Range

WHsensors commonly packages its products, including theWH131 serise Industrial Pressure Sensor with a?compound pressure range. The sensor is calibrated with a zero offset in order to measure vacuum. This feature is used in refrigeration applications to notify the user when a system has been evacuated. This particular model is also packaged as sealed gauge reference. As mentioned above, it seals the housing from changes in barometric pressure and protects the electronics from conditions such as icing or high pressure washdown.

One example of an WH131 model would be:

1/4" NPT Male pressure port

-14.7 to 100 PSI

4-20mA output signal

Mini-DIN43650C electrical connection

316L SS wetted materials

Internal restrictor plug; Sealed Gauge reference

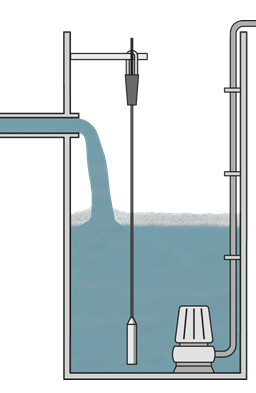

Differential Pressure Transducers

WHsensors offers the WH202 Differential Pressure Transducer?in various building controls applications. From water pressure flow to filtration applications, the WH202 is a compact transducer with an excellent price and performance. This DP is available in explosion proof and non-incendive packages for onshore and offshore refrigeration applications. It replaces traditional process style differential pressure transmitters as a compact device providing either a 4-20mA or voltage output signal.